About Know more about us

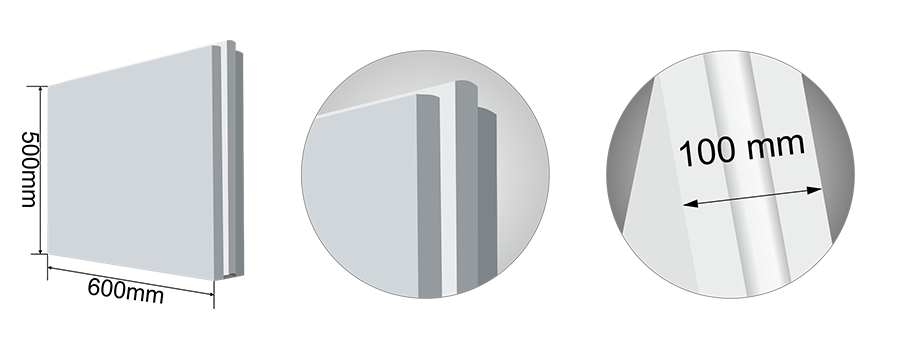

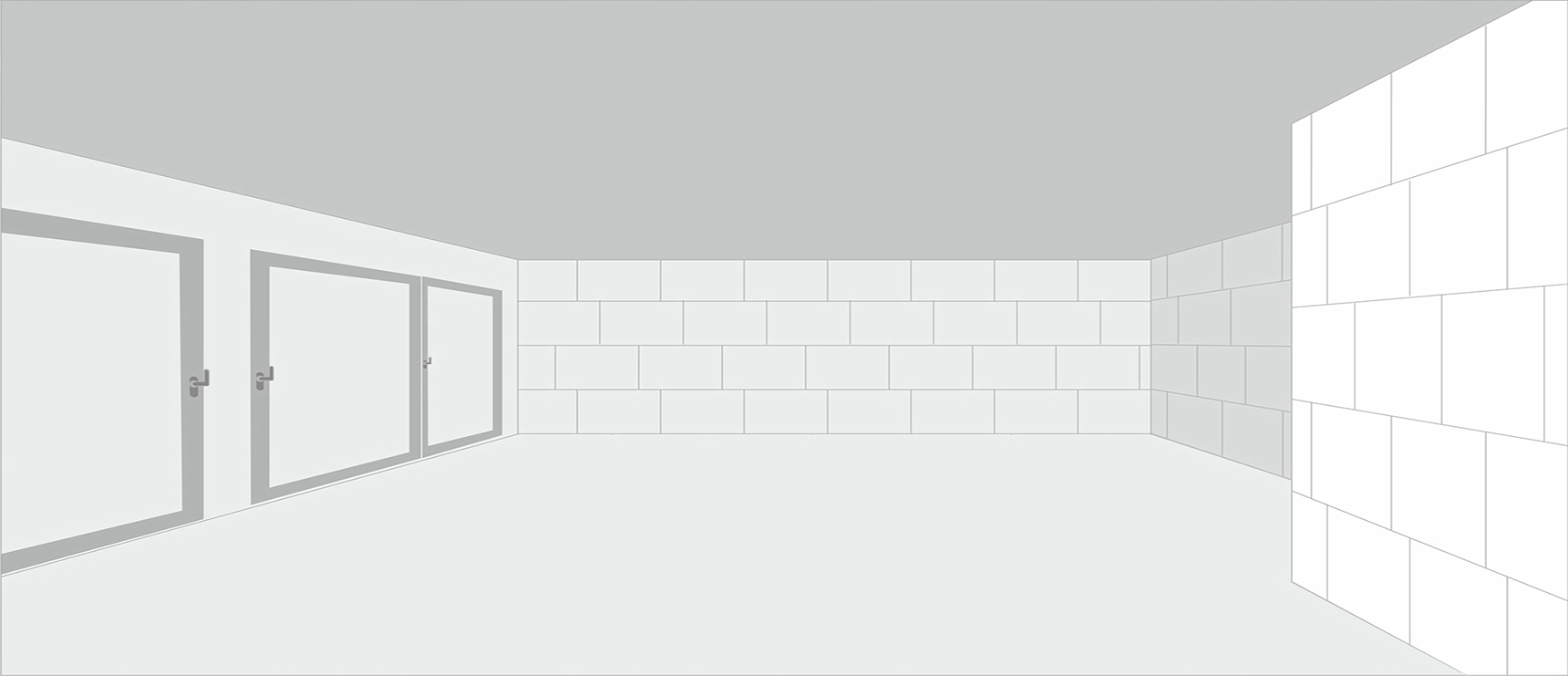

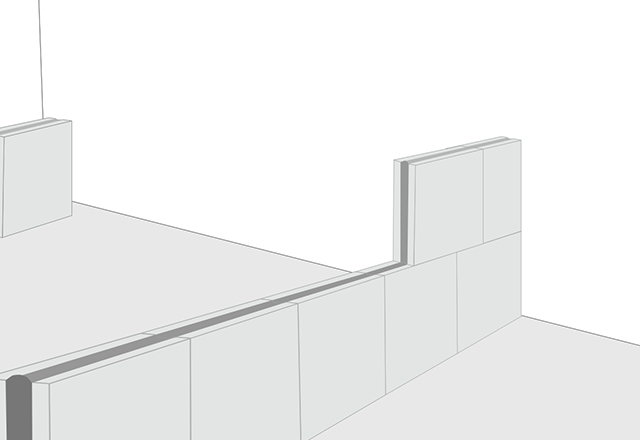

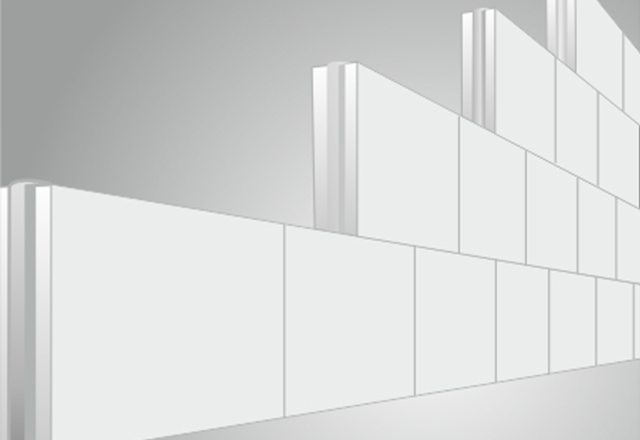

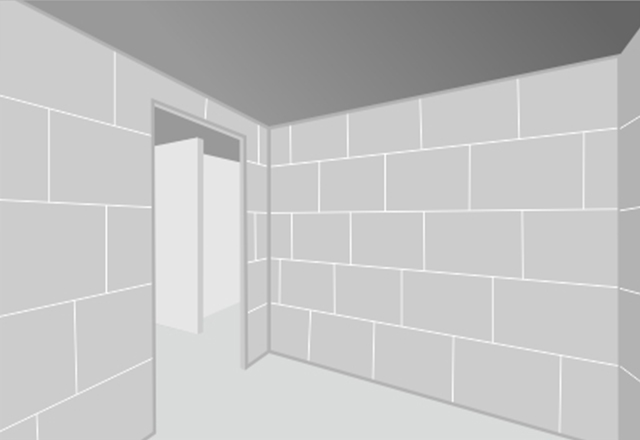

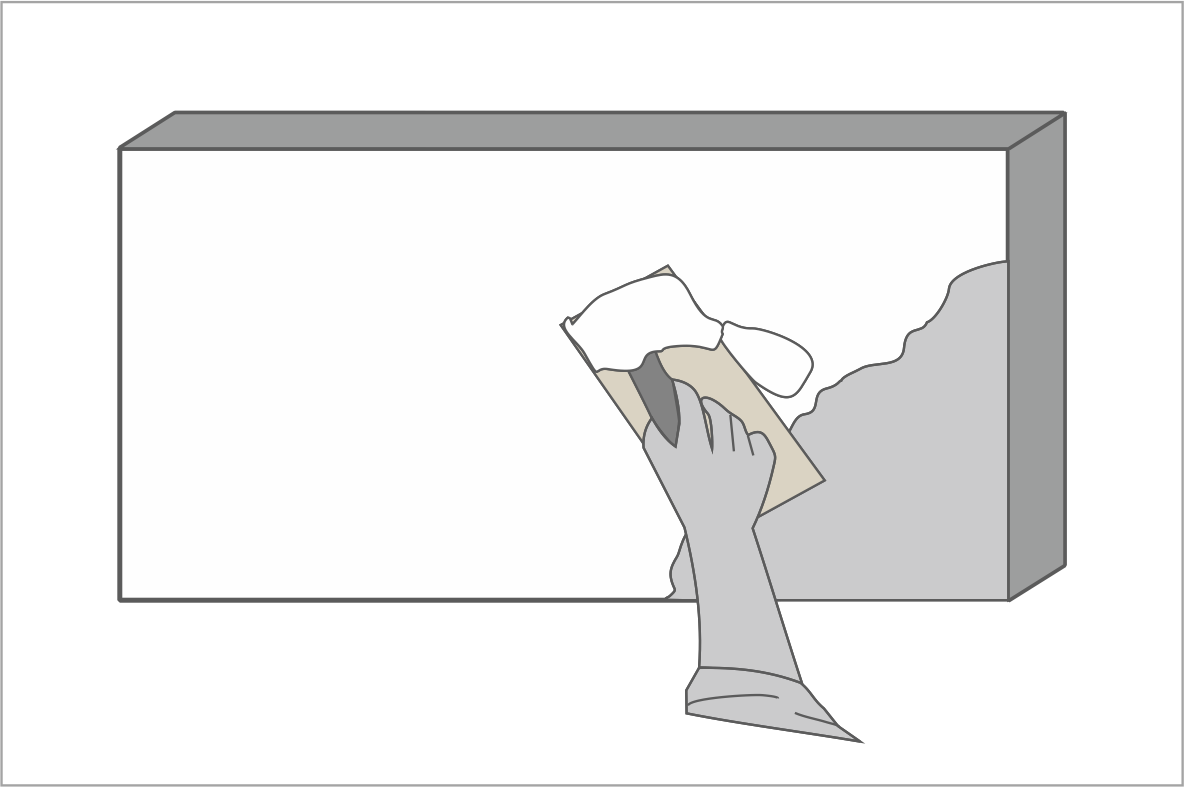

GYPTECH D-WALL is an internal wall solution that uses gypsum blocks (made using calcium sulphate as a base material). These blocks combine the benefits of conventional masonry with contemporary drywall construction. It has all the qualities of masonry: solid, void-free and highly stable; but better as it doesn’t require mortar, sand or plaster. This means the walls are to large degree built without water, Just like dry walls, but not similar to conventional dry walls. For distinction this construction with gypsum blocks is often referred to as massive drywall construction